Contributing Writer

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Categories

- Additive Manufacturing

- Aluminum Welding

- Arc Welding

- Assembly and Joining

- Automation and Robotics

- Bending and Forming

- Consumables

- Cutting and Weld Prep

- Electric Vehicles

- En Español

- Finishing

- Hydroforming

- Laser Cutting

- Laser Welding

- Machining

- Manufacturing Software

- Materials Handling

- Metals/Materials

- Oxyfuel Cutting

- Plasma Cutting

- Power Tools

- Punching and Other Holemaking

- Roll Forming

- Safety

- Sawing

- Shearing

- Shop Management

- Testing and Measuring

- Tube and Pipe Fabrication

- Tube and Pipe Production

- Waterjet Cutting

Industry Directory

Webcasts

Podcasts

FAB 40

Advertise

Subscribe

Account Login

Search

Die Basics 101: Production methods to make stamped parts

- By Art Hedrick

- Updated July 18, 2018

- August 9, 2005

- Article

- Bending and Forming

|

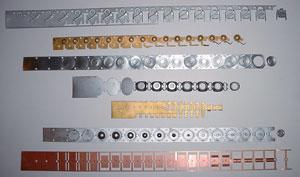

Figure 1 |

Among the many factors to consider when choosing a production method are the production speeds necessary to produce the required quantity within a given time frame; the material consumption needed for each part; the production method cost; preventive maintenance requirements; equipment availability; and the part shape, size, and geometric tolerance specified.

Line Dies

Line dies are tools that typically are hand or robotically loaded. Often each station that forms or cuts the sheet metal represents a single operation die. Hand-loaded line dies usually lend themselves to low-production parts or those that are too big and bulky to handle with automation. Several line dies usually can be placed within a single press. This allows the operator to transfer the parts from die to die to with a minimal travel distance.

Larger line dies often are placed in individual presses close together in a line, an arrangement referred to as tandem line presses (Figure 1).

Some line die advantages are:

- They often cost less than more complicated dies.

- They can be timed to run together in a common press.

- The operation's simplicity allows the part to be turned over or rotated in any axis by the operator or robot if necessary. This often allows for more complex geometries to be created.

- Smaller individual tools are lighter and can be handled with lower-cost die handling equipment.

- Maintaining a single station does not require removing all the dies.

Common line die disadvantages are:

- They often cannot compete with production speeds achievable with other methods, such as progressive dies.

- They require expensive robots or human labor.

- They often require several presses to manufacture a single part.

Transfer Dies

Transfer dies are special line dies that are timed together and properly spaced an even distance apart in a single press. The distance between each die is referred to as the pitch, or the distance the part must travel between stations.

|

Figure 2 |

Unlike with conventional line dies, the piece parts are transferred by special traveling rails mounted within the press boundaries. These rails most commonly are mounted on each side of the dies. During the press cycle, each rail travels inward, grabs the part with special fingers, and then transfers it to the next die.

Transfer systems can perform numerous motions. However, the two basic types are 2-D (two-axis) and 3-D (three-axis). Two-axis transfers move inward, grip the part, and slide it forward to the next station. Three-axis transfers move in, grip the part, pick it up vertically, move it to the next station, and lower it down onto the die. This third-axis movement allows the part to be placed within the perimeter gauging boundaries. Transfer systems are popular for manufacturing axial-symmetrical (round), very deep-drawn parts (Figure 2).

Some transfer system advantages are:

- Large parts can be handled at fairly rapid speeds.

- Stamped parts can be turned over or rotated during the transfer process.

- Servodrive-type transfers can be programmed to accommodate a large variety of parts, press speeds, and stroke lengths.

- Transfer dies do not tie each part together, often allowing for material savings.

- Large volumes of parts can be produced in a fairly short time frame.

Some transfer system disadvantages are:

- They often are quite costly.

- They often require sophisticated electronics and mechanical finger motion to function properly.

- They require more die protection sensors.

- They require a blank destacking system.

|

Figure 3 |

Progressive Dies

The progressive die is one of the most common, fastest methods available for producing piece parts. Unlike line or transfer dies, progressive dies tie the parts together by a portion of the original strip or coil, which is called a strip carrier. Different types of parts require different carrier designs.

Progressive dies can produce as few as seven or eight parts per minute or as many as 1,500 parts per minute. Unlike transfer or line dies, all necessary stations are mounted on a single common die set. These stations are timed and sequenced so that the piece part can be fed ahead a constant given distance called the progression or pitch. Many parts can be tied together allowing many parts to be made with each single press stroke.

Progressive dies most commonly are coil-fed, and if they contain the proper sensing system, they often can run unattended. It is not uncommon for a single press operator to run two or three progressive dies. The coil material typically is pushed through the die; however, systems that can pull and push the coil material through the die are available. Progressive dies usually require the use of a coil feeder and stock straightener (Figures 3 and 4).

|

Figure 4 |

Progressive die advantages are:

- They can produce a great volume of parts very quickly.

- They often can run unattended.

- They require only one press.

Progressive die disadvantages are:

- They usually cost more than line or transfer dies.

- They often require precision alignment and setup procedures.

- They require a coil feeder system.

- They require an open-ended press to allow for the metal to feed into the die.

- Damage to a single station requires removing the entire die set.

- They often are much heavier than single-station line dies.

The production method you choose depends on many factors. Carefully consider items such as the required volume of parts, your labor rates, and your existing equipment before choosing a production method for your stamped parts.

Editor's Note:

Part I provides an introduction to stamping.

Part II covers various forming operations.

Part III discusses several production methods used to make stamped parts.

Part IV and Part V cover common stamping die components.

Part VI explains specialty die components.

Part VII provides an overview of metals used in stamping, and Part VIII continues this discussion.

Part IX covers the mechanical properties as well as behavioral characteristics of metals.

Part X begins an in-depth look at the metal cutting process.

Part XI defines slug pulling and common causes.

Part XII describes methods for resolving slug-pulling problems.

Part XIII discusses various specialty metal cutting methods used in stamping operations.

Part XIV explains fineblanking and GRIPflow®.

Part XV describes several bending methods—wipe, coin relief, pivot, and V bending.

Part XVI continues the discussion of bending in stamping operations, focusing on rotary and reverse U bending. It also addresses the advantages and disadvantages of rotary bending.

Part XVII discusses the fundamentals of drawing and stretching.

About the Author

Art Hedrick

10855 Simpson Drive West Private

Greenville, MI 48838

616-894-6855

Related Companies

subscribe now

The Fabricator is North America's leading magazine for the metal forming and fabricating industry. The magazine delivers the news, technical articles, and case histories that enable fabricators to do their jobs more efficiently. The Fabricator has served the industry since 1970.

start your free subscription- Stay connected from anywhere

Easily access valuable industry resources now with full access to the digital edition of The Fabricator.

Easily access valuable industry resources now with full access to the digital edition of The Welder.

Easily access valuable industry resources now with full access to the digital edition of The Tube and Pipe Journal.

- Podcasting

- Podcast:

- The Fabricator Podcast

- Published:

- 04/16/2024

- Running Time:

- 63:29

In this episode of The Fabricator Podcast, Caleb Chamberlain, co-founder and CEO of OSH Cut, discusses his company’s...

- Trending Articles

AI, machine learning, and the future of metal fabrication

Employee ownership: The best way to ensure engagement

Steel industry reacts to Nucor’s new weekly published HRC price

Dynamic Metal blossoms with each passing year

Metal fabrication management: A guide for new supervisors

- Industry Events

16th Annual Safety Conference

- April 30 - May 1, 2024

- Elgin,

Pipe and Tube Conference

- May 21 - 22, 2024

- Omaha, NE

World-Class Roll Forming Workshop

- June 5 - 6, 2024

- Louisville, KY

Advanced Laser Application Workshop

- June 25 - 27, 2024

- Novi, MI